Jun 30, 2025

In the wave of agricultural modernization and ecological environment protection, the innovation of soil monitoring technology has become a key link. Solar soil EC sensors, driven by green energy, precise data collection, and wireless intelligent transmission, are leading the field of soil monitoring towards a new era of efficiency and sustainability. Whether it is precise management of smart agriculture or long-term monitoring of the ecological environment, these sensors have demonstrated irreplaceable value.

1、 Technological Innovation: Integration of Green Energy and Precise Sensing

The core advantage of solar soil EC sensors lies in their deep integration of solar power supply and high-precision sensing technology. Traditional soil sensors rely on batteries or external power sources, which pose challenges such as short battery life, high replacement costs, and complex wiring. However, solar soil EC sensors convert light energy into electrical energy through efficient solar panels, providing continuous and stable energy for the equipment. Even in environments with weak lighting, sensors can reduce energy consumption through low-power designs such as sleep wake mechanisms, ensuring long-term stable operation.

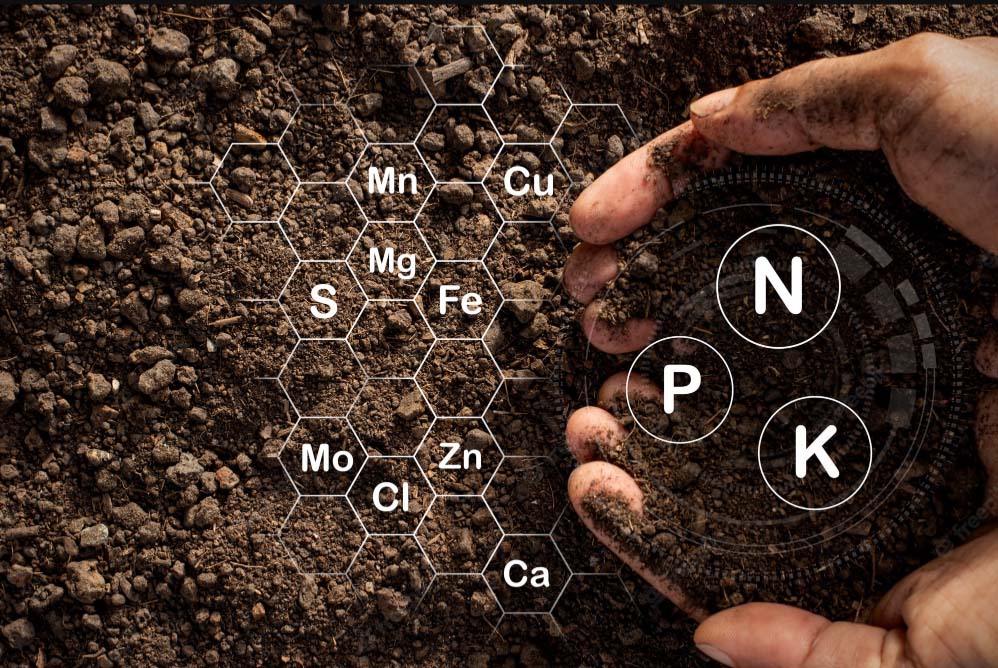

At the level of sensing technology, the sensor adopts advanced electrode and circuit design, which can quickly and accurately capture subtle changes in soil conductivity (EC value). EC value, as a key indicator reflecting soil salinity, nutrients, and moisture status, its accurate measurement directly affects the accuracy of subsequent decision-making. In addition, most solar soil EC sensors also integrate temperature and humidity monitoring functions, presenting users with a more comprehensive soil environment data map through multi parameter synchronous collection.

2、 Functional Features: Efficient, Stable, and Intelligent

(1) High precision measurement and fast response

The solar soil EC sensor has excellent measurement accuracy, which can control the error within a very small range and even identify small fluctuations in soil salt concentration. This high-precision feature enables it to provide reliable decision-making basis for agricultural production. At the same time, the rapid response mechanism of sensors can complete data acquisition and transmission in a short period of time, meeting the needs of real-time monitoring. For example, during the irrigation process, sensors can quickly sense changes in soil moisture and salinity, provide timely feedback data, and help users adjust irrigation strategies.

(2) Strong anti-interference and environmental adaptability

The outdoor environment is complex and varied, and factors such as other ions, impurities, and electromagnetic interference in the soil may affect the measurement accuracy of sensors. The solar soil EC sensor effectively resists external interference and ensures data stability and reliability through optimized circuit design and signal processing algorithms. In terms of structural design, it adopts waterproof, dustproof, and corrosion-resistant shell materials, which can adapt to extreme environments such as high temperature, low temperature, and high humidity. Whether it is arid desert farmland or humid swamp monitoring areas, it can operate stably.

(3) Wireless transmission and intelligent management

Based on low-power wide area network technologies such as LoRa and NB IoT, solar soil EC sensors have achieved long-distance wireless transmission of data. Sensors can quickly send data to a central system or cloud platform without the need for complex wiring engineering. Users can view soil data in real-time, generate analysis reports, and set threshold alarms through mobile apps or computer terminals. This intelligent management mode greatly improves monitoring efficiency and reduces labor costs.

3、 Diversified Applications: Comprehensive Coverage from Agriculture to Ecology

(1) Smart Agriculture: The 'Digital Steward' for Precise Planting

In the field of smart agriculture, solar soil EC sensors are the core equipment for achieving precise irrigation and scientific fertilization. By monitoring soil EC values, temperature and humidity in real-time, sensors can help farmers determine soil fertility status and crop water and fertilizer requirements. For example, when the soil salinity is too high, sensors promptly issue warnings to remind farmers to adjust irrigation water volume and frequency to avoid soil salinization; In the fertilization process, based on soil nutrient data, farmers can accurately mix fertilizers, reduce resource waste, and improve crop yield and quality. In addition, sensors can also be linked with automatic irrigation systems and fertilization equipment to achieve automation and intelligence in agricultural production.

(2) Horticulture and Forestry: Powerful Assistants for Fine Maintenance

In horticultural planting, different flowers and green plants have different requirements for soil environment. Solar soil EC sensors can help horticulturists real-time grasp soil conditions, provide suitable growth conditions for plants, and enhance ornamental value. In the forestry field, this sensor can be used to monitor the health status of forest soil, prevent soil degradation, and provide data support for forest ecological restoration and sustainable management.

(3) Environmental monitoring: the forefront sentinel of ecological protection

Solar soil EC sensors play an important role in ecological environment monitoring. By deploying sensors in natural reserves, wetlands, mining areas, and other areas, long-term monitoring of soil environmental changes can be achieved, and ecological problems such as soil pollution and salinization can be detected in a timely manner. For example, in the vicinity of mining areas, sensors can monitor real-time changes in soil heavy metal content and conductivity, providing scientific basis for soil remediation and ecological reconstruction, and helping to maintain ecological balance.

4、 Future Outlook: Technological Upgrades and Application Expansion

With the continuous development of technologies such as the Internet of Things, big data, and artificial intelligence, solar soil EC sensors will also usher in new changes. In the future, sensors may integrate more monitoring parameters (such as soil pH value, heavy metal content, etc.) to achieve more comprehensive soil environmental monitoring; In terms of data processing, with the help of artificial intelligence algorithms, sensors can conduct in-depth analysis of monitoring data and provide more forward-looking decision-making recommendations. In addition, with the reduction of costs and improvement of performance, solar soil EC sensors are expected to be applied in more fields, contributing greater strength to global agricultural development and ecological protection.

Solar soil EC sensors, with their green, precise, and intelligent characteristics, are reshaping the mode and pattern of soil monitoring. From fields to ecological reserves, from traditional agriculture to smart agriculture, it is becoming an important technological support for promoting agricultural modernization and ecological sustainable development. With the continuous innovation of technology, we have reason to believe that solar soil EC sensors will play a greater role in the future, opening a new chapter in precise monitoring and intelligent management.

Read More